· Direct conversion of HL HRA ,HRB ,HRC ,HB .HV, HS; Conversion to tensile strength

· Matrix LCD, showing all functions

· Menu operation, easily to operate

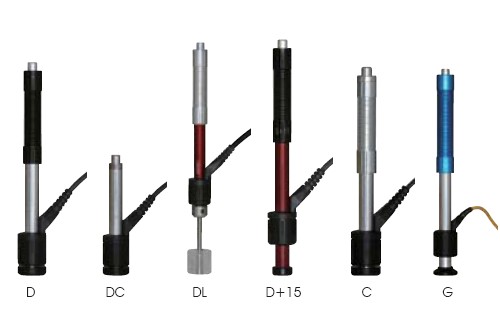

· Seven different kinds of impact device are available, distinguish automatically, no need calibration

· On-board memory holds 48-350 groups of data

· Upper/lower limits setting and sound alarm

· Help key is available for all the operation interfaces

· Backlight for convenient use in darkness

· Software calibration

· Any test value can be printed directly

· RS232 connector, many connecting ways to satisfy different requirements

· Easy to replace rechargeable battery

· Easy to change rechargeable battery

Technical Specification

Measuring range

(170-960)HLD (17.9-69.5)HRC

Hardness scale

HLD,HB,HS,HRA,HRB,HRC,HV

Measuring direction

360°

Tolerance

±6HLD(when HLD=760)

Repeatability

6HLD(when HLD=760)

Diameter of printer paper

40mm

Width of printer paper

44.5±0.5mm

Power

12V/600mmA

Charging time

2-3.5 hour

Humidity

≤90%

Operating temperature

0℃-40℃

Weight

0.6kg

Overall dimensions

234×88×46mm

Max.Workpiece Hardness

Refer to "Technical specification of

impact devices" below

Min.Radius of

Workpiece (convex/concave)

Min. Workpiece weight

Min. Workpiece thickness

Min. thickness of

hardened layers

Measuring range

Refer to “wide measuring range of

hardness testers” and

"testing accuracy and repeatability" below

Accuracy

-

The application of Leeb hardness tester

It can be wildly used in petroleum, mechanism, chemical engineering, metallurgy, aeration and space,

pressure vessel and so on industries. It works primarily by checking the hardness to do the invalidation analysis.The advantage of Leeb hardness tester (compared with the bench one): convenience:

when the checked unit is large-sized, hard to move or need check on the spot, under this circumstances, only the Leeb hardness tester fits.1. Primary use

l Installed machine or abiding assembly parts; such as boiler, metal pipes and turbo vanes.

l Mould; large producing part: roller, crank, tramroad of the machine and so on.

l Invalidation analysis of pressure vessel, steam generator and other equipments.

l The narrow space in the main shaft and the bottom of groove.

l The product line of bearings and other parts.

l Demanding the original records of the results

l Distinguishing of materials in the metal material warehouse.

2. Idiographic application

1). Aeration and space: being used in the examination of engine and structural parts of plane,

the engine structure repairing manual prescribes that some components and parts are forbidden to disassemble,

in addition, some parts are very difficult to remove. Then we can use the Rockwell hardness tester to deal with it.

For example, when the plane engine catch fire, we should check the influenced area by hardness tester to determine

the repairing area. Some other large construal parts need the portable Leeb hardness tester, such as: all grades of turbo plate,

high and low pressure turbo shaft.2). Mechanical manufacture

Machine industry: checking the machine body, leg, the track face of sliding saddle and so on.

Heat treatment industry: checking the hardness of the vulcanized layer treated by cementite, quencher.

Car industry: generate parts, crank, cylinder cover, inner cavity, cylinder, bearing bush, redirector.

Engine factory: crank, bearing and large casting.

. Gas-engine factory: body of the engine, crank, camshaft, connecting bar, press cover of flywheel,

bushing cover and so on.

Home appliance industry: air condition, refrigerator, washer, and in addition, the hardness testing of

tooth flank, cavity of mould.

3). Boiler and pressure vessel industry: The main testing parts of boiler is pipes, air bags. They are connected with expansion. According to the regulation, before the expansion, the pipe and the air bag both need hardness testing to insure the hardness of airbag is higher than the pipe’s.

4). Petroleum and chemical engineering industry: In this industry, hardness tester is wildly used in the examination of pipeline and vessles.

5). Power station ( thermoelectricity ): pyrobolts, impellers.

6). Universities and institutes: Usually used for teaching or scientific research, analyzing the metal material with Rockwell hardness tester.

Standard delivery

●Main unit

●Impact device type D

●Small support ring

●Printing paper

●Nylon brush

●Leeb hardness test block

●Charger

●Certificate

●Warranty card

●Instruction manual

Optional accessories

●Communication cable

●Special impact device

●Support rings

●Nylon brush(when selecting impact device type G)-Advanced Leeb Hardness Model with In-built printer

-Automatic identification of Impact devices

High performance rechargeable battery, intelligent charging management

Optional Software to connect with PC,Support data query, storage,

statistics and histogram display and other functions

-Upper and lower limit and sound alarm

Impact devices Application :

Impact device D :

For the majority of the hardness measurement

Impact device DC:

For very small place ( holes, cylindrical Park) measurement

Impact device D + 15

For the groove or concave surface hardness measurement

Impact device E

For extremely high hardness, high content of carbide tool steel hardness measurement

Impact device C

For surface hardening components, surface covering layer, the hardness measurement of thin wall

Impact device G

Only for the dense parts which Brinell hardness value in the range of 650HB hardness measurement

Impact device DL