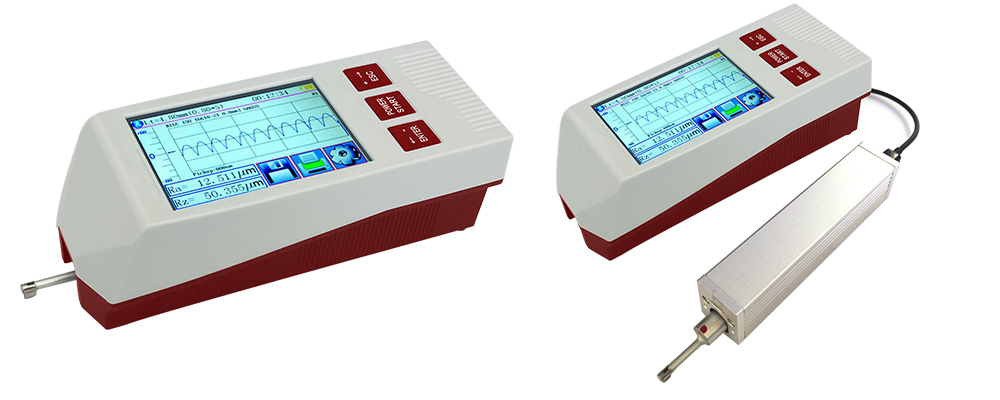

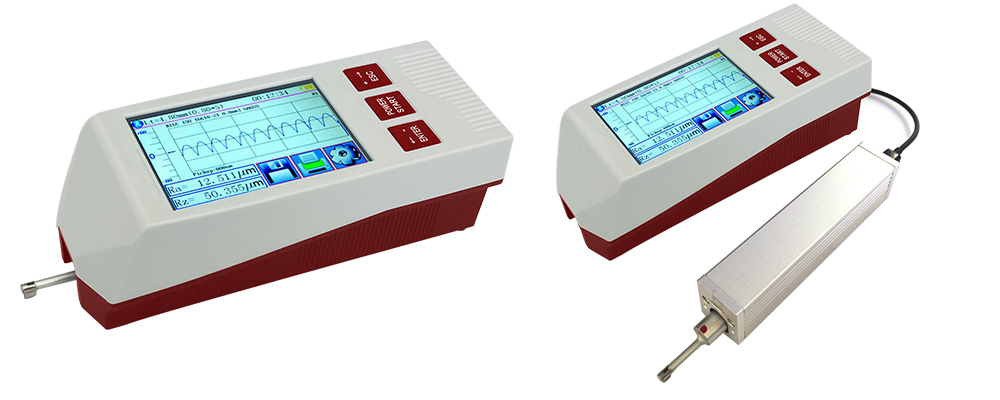

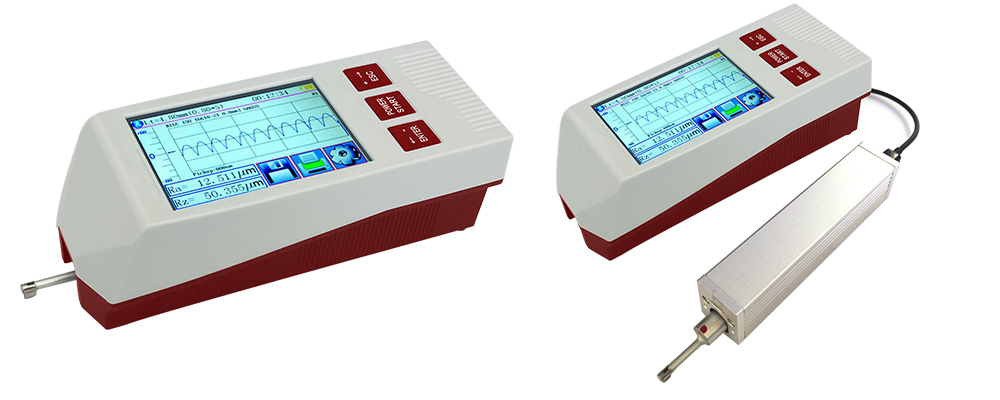

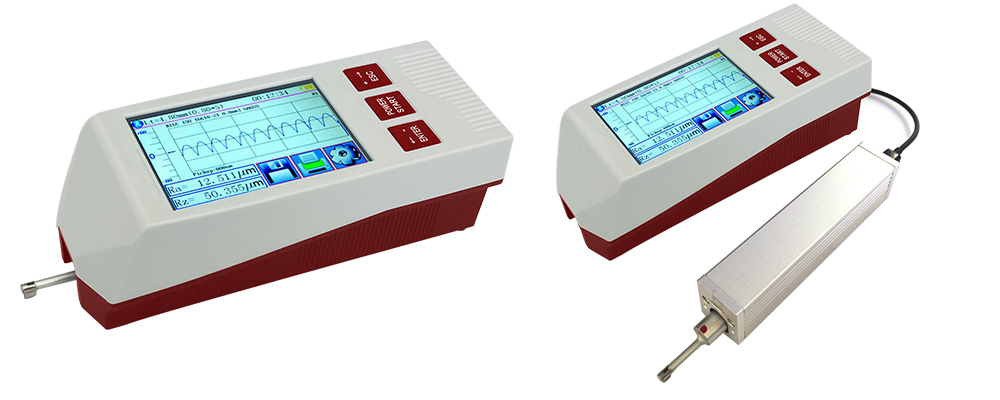

- Main Featurel Mechatronics and ergonomics design, small size, light weight, easy to operationl The stylus drive unit can be stored within the main unit for standard measurement, or separated from the display unit by using the supplied cable which allows more flexible measurement in any orientation. The driver can be separated and reattached in one simple step.l DSP chip control and data processing, high speed, low power consumptionl 22 Parameters: Ra ,Rz, Rq, Rt, Rp ,Rv, R3z, R3y, Rz(JIS), Rs, Rsk, Rsm, Rku, Rmr, Ry(JIS), Rmax,RPc, Rk, Rpk, Rvk, Mr1, Mr2l Measurement range up to 160¦Ìm (can be optional to 320¦Ìm)l 3.5 inches color graphic TFT touch screen, wide viewing angle, excellent readability and an intuitive rich display, it includes a backlight to improve visibility in dark environmentsl Can be operated using buttons or touch screenl 2.It provide Bluetooth Capability , support wireless connection with mobile and mini printer.l Built-in lithium-ion rechargeable battery and control circuit, high capacity, no memory effect, it works over 50 hours while fully charged, and there is remaining charge indicator, charging hintl Large capacity data storage, 100 item of raw data and curves can be storedl Real-time clock setting and display for easy data recording and storagel With auto sleep, auto power off, power-saving featuresl Reliable circuit and software design to preventing the motor stuckl Language: Chinese and English switch freelyl All parameters or any of the parameters which set by users can be printedl Optional accessories: Bluetooth capability, curved sensor, pinholes sensors, measurement, stand, extension rod, printerl Portable Surface Roughness Tester ART300 complies with international standards ISO, DIN, ANSI, JISTechnical SpecificationMeasurement RangeThe Z axis (vertical)¡À80¦Ìm/¡À160 µm£¨enhanced model£©The X axis (Transverse)20mmResolutionThe Z axis (vertical)0£®01¦Ìm/¡À20¦Ìm0£®02¦Ìm/¡À40¦Ìm0£®04¦Ìm/¡À80¦Ìm0£®08¦Ìm/¡À160¦ÌmMeasurement itemParameterRa,Rz,Rq,Rt£¬Rp,Rv,R3z,R3y,Rz(JIS),Rs,Rsk,Rsm,Rku,Rmr,Ry(JIS), Rmax, RPc, Rk, Rpk, Rvk, Mr1, Mr2)StandardISO,ANSI,DIN,JISGraphicBearing area curve, Roughness profile, Primary profileFilterRC,PC-RC,Gauss,D-PThe sampling length(lr)0.25, 0.8, 2.5mmAssessment length£¨ln£©Ln= lr¡Án n=1~5SensorMeasuring methodskiddedStylus tipDiamond, 90 cone angle, 5¦ÌmRForce<4mNSkid parthard alloy, skid radius of curvature: 40mmTraversing speedlr=0.25, Vt=0.135mm/slr=0.8, Vt=0. 5mm/slr=2. 5, Vt=1mm/sReturn Vt=1mm/sAccuracyLess than ¡À10%RepeatabilityLess than 6%Power supplyBuilt-in Lithium ion battery, Charger :DC5V,800mAOutline dimensionMain unit: 64*53*160mm drive: 23*27*115mmWeight£¨main unit£©Around 380gworking EnvironmentTemperature: - 20¡æ ~ 40¡æHumidity: < 90% RHStore and TransportationTemperature: - 40¡æ ~ 60¡æHumidity: < 90% RH

RangeRa,Rq0.005¦Ìm ~ 30¦ÌmRz,R3z,Ry,Rt,Rp,Rm0.02¦Ìm ~ 320¦ÌmSk0 ~ 100%S,Sm1mmtp0 ~ 100%

Measuring Range

- Main Featurel Mechatronics and ergonomics design, small size, light weight, easy to operationl The stylus drive unit can be stored within the main unit for standard measurement, or separated from the display unit by using the supplied cable which allows more flexible measurement in any orientation. The driver can be separated and reattached in one simple step.l DSP chip control and data processing, high speed, low power consumptionl 22 Parameters: Ra ,Rz, Rq, Rt, Rp ,Rv, R3z, R3y, Rz(JIS), Rs, Rsk, Rsm, Rku, Rmr, Ry(JIS), Rmax,RPc, Rk, Rpk, Rvk, Mr1, Mr2l Measurement range up to 160¦Ìm (can be optional to 320¦Ìm)l 3.5 inches color graphic TFT touch screen, wide viewing angle, excellent readability and an intuitive rich display, it includes a backlight to improve visibility in dark environmentsl Can be operated using buttons or touch screenl 2.It provide Bluetooth Capability , support wireless connection with mobile and mini printer.l Built-in lithium-ion rechargeable battery and control circuit, high capacity, no memory effect, it works over 50 hours while fully charged, and there is remaining charge indicator, charging hintl Large capacity data storage, 100 item of raw data and curves can be storedl Real-time clock setting and display for easy data recording and storagel With auto sleep, auto power off, power-saving featuresl Reliable circuit and software design to preventing the motor stuckl Language: Chinese and English switch freelyl All parameters or any of the parameters which set by users can be printedl Optional accessories: Bluetooth capability, curved sensor, pinholes sensors, measurement, stand, extension rod, printerl Portable Surface Roughness Tester ART300 complies with international standards ISO, DIN, ANSI, JIS

Technical SpecificationMeasurement RangeThe Z axis (vertical)¡À80¦Ìm/¡À160 µm£¨enhanced model£©The X axis (Transverse)20mmResolutionThe Z axis (vertical)0£®01¦Ìm/¡À20¦Ìm0£®02¦Ìm/¡À40¦Ìm0£®04¦Ìm/¡À80¦Ìm0£®08¦Ìm/¡À160¦ÌmMeasurement itemParameterRa,Rz,Rq,Rt£¬Rp,Rv,R3z,R3y,Rz(JIS),Rs,Rsk,Rsm,Rku,Rmr,Ry(JIS), Rmax, RPc, Rk, Rpk, Rvk, Mr1, Mr2)StandardISO,ANSI,DIN,JISGraphicBearing area curve, Roughness profile, Primary profileFilterRC,PC-RC,Gauss,D-PThe sampling length(lr)0.25, 0.8, 2.5mmAssessment length£¨ln£©Ln= lr¡Án n=1~5SensorMeasuring methodskiddedStylus tipDiamond, 90 cone angle, 5¦ÌmRForce<4mNSkid parthard alloy, skid radius of curvature: 40mmTraversing speedlr=0.25, Vt=0.135mm/slr=0.8, Vt=0. 5mm/slr=2. 5, Vt=1mm/sReturn Vt=1mm/sAccuracyLess than ¡À10%RepeatabilityLess than 6%Power supplyBuilt-in Lithium ion battery, Charger :DC5V,800mAOutline dimensionMain unit: 64*53*160mm drive: 23*27*115mmWeight£¨main unit£©Around 380gworking EnvironmentTemperature: - 20¡æ ~ 40¡æHumidity: < 90% RHStore and TransportationTemperature: - 40¡æ ~ 60¡æHumidity: < 90% RH

Technical SpecificationMeasurement RangeThe Z axis (vertical)¡À80¦Ìm/¡À160 µm£¨enhanced model£©The X axis (Transverse)20mmResolutionThe Z axis (vertical)0£®01¦Ìm/¡À20¦Ìm0£®02¦Ìm/¡À40¦Ìm0£®04¦Ìm/¡À80¦Ìm0£®08¦Ìm/¡À160¦ÌmMeasurement itemParameterRa,Rz,Rq,Rt£¬Rp,Rv,R3z,R3y,Rz(JIS),Rs,Rsk,Rsm,Rku,Rmr,Ry(JIS), Rmax, RPc, Rk, Rpk, Rvk, Mr1, Mr2)StandardISO,ANSI,DIN,JISGraphicBearing area curve, Roughness profile, Primary profileFilterRC,PC-RC,Gauss,D-PThe sampling length(lr)0.25, 0.8, 2.5mmAssessment length£¨ln£©Ln= lr¡Án n=1~5SensorMeasuring methodskiddedStylus tipDiamond, 90 cone angle, 5¦ÌmRForce<4mNSkid parthard alloy, skid radius of curvature: 40mmTraversing speedlr=0.25, Vt=0.135mm/slr=0.8, Vt=0. 5mm/slr=2. 5, Vt=1mm/sReturn Vt=1mm/sAccuracyLess than ¡À10%RepeatabilityLess than 6%Power supplyBuilt-in Lithium ion battery, Charger :DC5V,800mAOutline dimensionMain unit: 64*53*160mm drive: 23*27*115mmWeight£¨main unit£©Around 380gworking EnvironmentTemperature: - 20¡æ ~ 40¡æHumidity: < 90% RHStore and TransportationTemperature: - 40¡æ ~ 60¡æHumidity: < 90% RH

RangeRa,Rq0.005¦Ìm ~ 30¦ÌmRz,R3z,Ry,Rt,Rp,Rm0.02¦Ìm ~ 320¦ÌmSk0 ~ 100%S,Sm1mmtp0 ~ 100%

Measuring Range

- ApplicationPortable Surface Roughness Tester ART300 allows surface roughness measurement both on metal and non-metal workpieces. It is suitable for machining and manufacturing, quality control, inspection departments, especially for measurement on large and heavy workpiece, assembly line on site. The ART300 is a Non Destructive Testing instrument, damage won¡¯t caused to testing piece.

- Standard Configration¡¤ART300 main unit 1 piece¡¤Sensor Drive 1 piece¡¤Standard Sensor 1 piece¡¤Calibration block and bracket 1 piece¡¤Height adapter 1 piece¡¤Power adapter 1 set¡¤Operating manualService PolicyIf the instrument is under proper operation, we implements three months replacement guaranteed, two years warranty (except vulnerability and consumable parts , eg: sensor, cable etc), and lifelong service.

- Optional TransducersService PolicyIf the instrument is under proper operation, we implements three months replacement guaranteed, two years warranty (except vulnerability and consumable parts , eg: sensor, cable etc), and lifelong service.