Product name: Leeb Hardness Tester Product category: Portable Hardness Tester Product type: AHT200 Price: Contact us Features

● LCD display of 128×64 matrix is used.

● Hardness scales(HV ,HB,HRC,HRB,HRA,HS).

● RS232 interface and USB to PC

● Max 600 groups(impact times:32~1)of data can be stored at internal.

● Back light display has been used to make convenient or the user in poor light.

● Upper and lower limit can be preset. It will alarm automatically when the result value exceeding the limit.

● Material of “cast steel” is added HB values can be read out directly when D/DC impact device is used to measure “cast steel” workpiece.

● Power is two of AA battery. Continuous working period: approx. 100 h (no back light on).

● Software of PC can be installed according to the requirements of user. The function will be more powerful to satisfy the more demands of quality control and management.

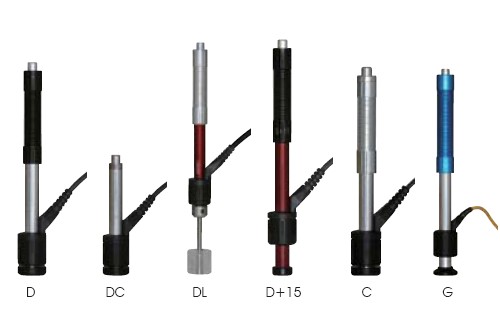

Impact devices Application :

Impact device D :

For the majority of the hardness measurement

Impact device DC:

For very small place ( holes, cylindrical Park) measurement

Impact device D + 15

For the groove or concave surface hardness measurement

Impact device E

For extremely high hardness, high content of carbide tool steel hardness measurement

Impact device C

For surface hardening components, surface covering layer, the hardness measurement of thin wall

Impact device G

Only for the dense parts which Brinell hardness value in the range of 650HB hardness measurement

Impact device DL

For deep trough bottom or surface ( such as a tooth ) and other parts of the measurement

Features

● LCD display of 128×64 matrix is used.

● Hardness scales(HV ,HB,HRC,HRB,HRA,HS).

● RS232 interface and USB to PC

● Max 600 groups(impact times:32~1)of data can be stored at internal.

● Back light display has been used to make convenient or the user in poor light.

● Upper and lower limit can be preset. It will alarm automatically when the result value exceeding the limit.

● Material of “cast steel” is added HB values can be read out directly when D/DC impact device is used to measure “cast steel” workpiece.

● Power is two of AA battery. Continuous working period: approx. 100 h (no back light on).

● Software of PC can be installed according to the requirements of user. The function will be more powerful to satisfy the more demands of quality control and management.

l Installed machine or abiding assembly parts; such as boiler, metal pipes and turbo vanes.

l Mould; large producing part: roller, crank, tramroad of the machine and so on.

l Invalidation analysis of pressure vessel, steam generator and other equipments.

l The narrow space in the main shaft and the bottom of groove.

l The product line of bearings and other parts.

l Demanding the original records of the results

l Distinguishing of materials in the metal material warehouse.

No.

Standard Delivery

1

Main unit

1

2

D type impact device

1

3

Small supporting ring

1

4

Nylon brush (A)

1

5

High value Leeb test block

1

6

Communication cable

1

7

AHT-200DataView Software

1

Impact Device D

Impact Device D Impact Device DC

Impact Device DC Impact Device D+15

Impact Device D+15 Impact Device DL

Impact Device DL Impact Device C

Impact Device C Impact Device G

Impact Device G Impact Device E

Impact Device E Printer

Printer